Product classification

Polyurethane sandwich panel

Product Introduction

Product Introduction

Dongan metal embossed surface composite insulation board has a good connection between the board and the board and the main structure, and provides a complete set of connectors and accessories, which not only meets the installation strength requirements, but also avoids the generation of cold (hot) bridge, the bending resistance of the embossed board, and the resistance to thermal expansion and cold contraction are improved.

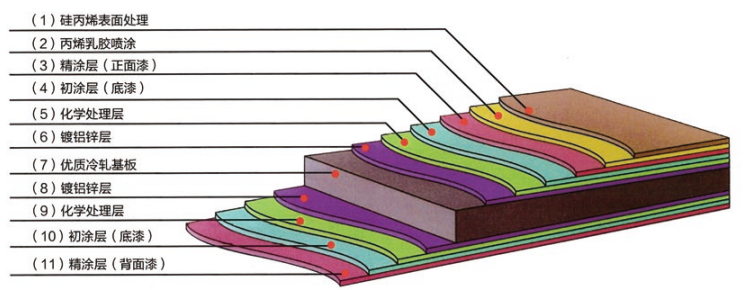

Surface material: high weather-resistant aluminum-zinc plated steel plate;

Sandwich material: high density polyurethane foam insulation layer;

Bottom material: moisture-proof and heat-insulating aluminum foil protective layer;

Fire rating: the highest B1 level;

Exterior wall panel specifications: thickness 16mm, width 383mm, length can be customized.

Product Features

●Thermal insulation: thermal insulation and energy saving

Compared with traditional exterior wall panels, metal carved panels have better heat preservation and heat insulation functions.

●Green environmental protection: implement the concept of energy conservation and environmental protection

The chemical and physical structure of the metal carved panel is stable, pollution-free, and has a long service life.

● Easy installation: convenient installation

Metal carved panel installation method is simple, not affected by the season and weather.

● Sound insulation noise reduction: sound insulation noise reduction quiet and comfortable

Metal carved panel is a closed bubble structure, with significant sound insulation effect.

● Waterproof and moisture-proof: waterproof and moisture-proof performance is stable

Metal carved panel after special process treatment, good waterproof performance, high material stability.

● Fire retardant: fire retardant performance fire hazard

After special treatment, the core material has good fire retardant performance.

● Shock-resistant crack: light texture, shockproof effect is obvious

Metal carved panel after special process treatment, with strong shock resistance, crack resistance characteristics.

● Diversity: Variety of patterns and colors

A wide range of metal carved panel patterns, there are more than a hundred different kinds of carved panel patterns and background color optional.

● Thin plate thickness: only 16mm, large container volume, low freight cost to square meters.

Product Application

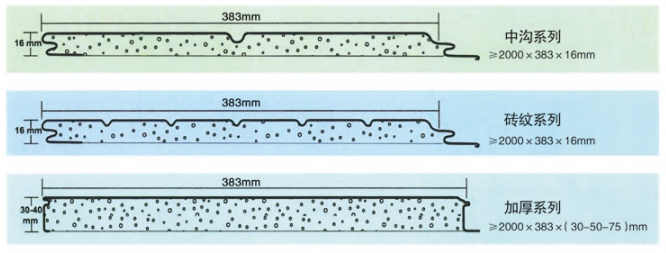

Wall panel specification

Packing specification | |

Weight | 3.7kg/m² |

Length | Custom |

Width | 383mm |

Thickness | Standard 16mm |

Standard size area | 1.532m ² |

Product standard size | 4000x383x16mm |

Packing size | 4000x415x135mm |

Packing quantity | 10 pieces/carton |

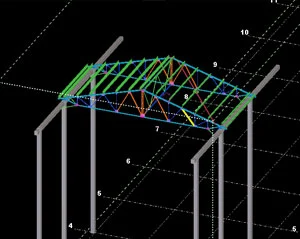

Schematic diagram of surface material structure

Key words:

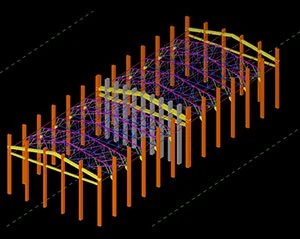

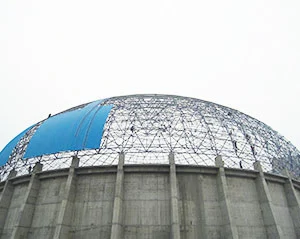

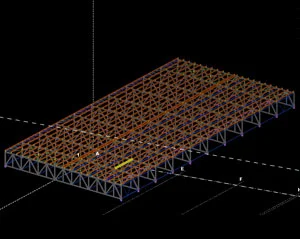

Related Cases

Get Quote