Product classification

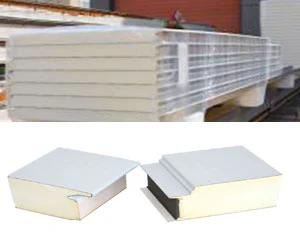

PU/PIR (Wall)

Product Introduction

Introduction to polyurethane core materials

New polyurethane core material: The raw materials, combined polyether (white material) and isocyanate (black material), are mixed at a certain ratio through a high-pressure machine and then evenly poured between the upper and lower layers of the panel, forming through lamination and foaming.Its density is 40kg/m3, thermal conductivity coefficient is 0.021w/m.k, water repellency >98%, combustion performance B1, B2, B3 levels, with prices ranging from high to low.

New polyurethane core material: The raw materials, combined polyether (white material) and isocyanate (black material), are mixed at a certain ratio through a high-pressure machine and then evenly poured between the upper and lower layers of the panel, forming through lamination and foaming.Combined polyether: Commonly known as white material. It is made from a mixture of polyether polyols, catalysts, foaming agents, flame retardants, and other components. Domestic brands include Wanhua Chemical and Wanhua Rongwei; international brands include BASF, Huntsman, Bayer.

New polyurethane core material: The raw materials, combined polyether (white material) and isocyanate (black material), are mixed at a certain ratio through a high-pressure machine and then evenly poured between the upper and lower layers of the panel, forming through lamination and foaming.Isocyanate: Polymer MDI (methylene diphenyl diisocyanate), commonly known as black material, with major brands being Wanhua Chemical, BASF, Bayer, Huntsman.

New polyurethane core material: The raw materials, combined polyether (white material) and isocyanate (black material), are mixed at a certain ratio through a high-pressure machine and then evenly poured between the upper and lower layers of the panel, forming through lamination and foaming.Characteristics and advantages of polyurethane sandwich panels

① The panels are uniform and stable with excellent thermal insulation and waterproof performance;

② Good airtightness (commonly used in cold storage);

③ Lightweight with an attractive appearance, effectively solving temperature differences in the refrigeration industry;

④ Easy and quick installation; sizes can be expanded or reduced according to needs;

⑤ Classified as B-level fireproof material;

⑥ Good surface flatness;

⑦ Superior water tightness;

⑧ No cold bridge phenomenon;

⑨ Lightweight structure;

⑩ Environmentally friendly and healthy

PU/PIR wall panel types

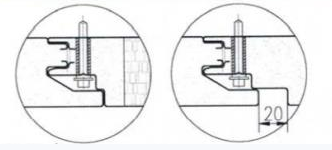

A. Water ripple effect, excellent decorative effect; under the influence of the water ripple effect, light shines on its surface creating light and dark stripes, extremely beautiful with a scene-changing effect. Effective width 1000mm, hidden screw connection.

B. Pure flat effect; smooth and even surface that serves as a decorative alternative to aluminum panel curtain walls. Effective width 1000mm, hidden screw connection.

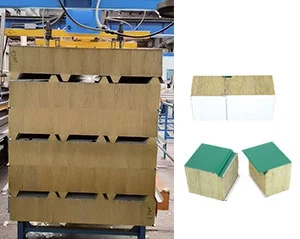

C. Visible nail panel; can be made into square wave or pure flat effects; suitable for mobile houses, dismountable houses, telecommunication rooms, purification rooms, etc., with consistent inner and outer surfaces and tight connections.

Name

|

PU/PIR hidden sandwich panel | Panel type |

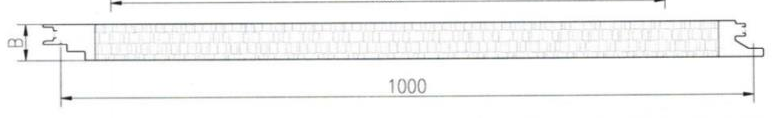

| DAY-1000 type (2) | Effective width | |

| Core material | 800mm/900mm/1000mm | |

| Core thickness | PU/PIR | |

| Steel plate thickness | 40mm/50mm/75mmm/80mm/100mm/120mm/150mm/200mm | |

| Performance | 0.4mm-1.0mm | |

| High insulation performance, fireproof B level, high strength, high rigidity, good water tightness | Visible nail plug-in sandwich panel |

|

PU/PIR hidden sandwich panel | DAC1000 type (2) |

| DAY-1000 type (2) | Application fields | |

| Core material | 950mm/1000mm | |

| Core thickness | PU/PIR | |

| Steel plate thickness | 40mm/50mm/75mmm/80mm/100mm/120mm/150mm/200mm | |

| Performance | 0.4mm-1.0mm | |

| High insulation performance, fireproof B level, high strength, high rigidity, good water tightness | Visible nail plug-in sandwich panel |

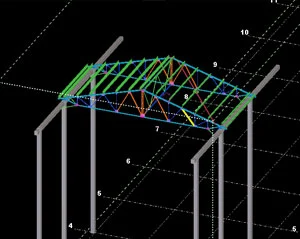

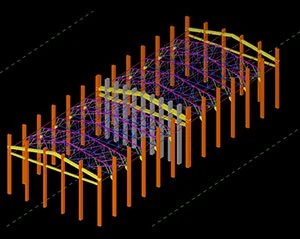

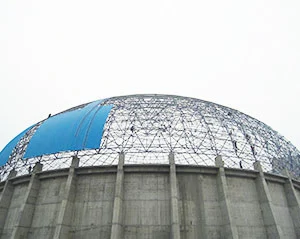

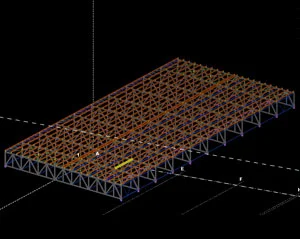

Industrial buildings, office buildings, public buildings, large stores, residential areas.

工业建筑、办公楼、公共建筑 、大型店铺、住宅、住宅等。

Key words:

Related Cases

Get Quote